Nearly 20% of temperature-sensitive health products are damaged during transit due to breaks in the cold chain. This staggering statistic highlights the immense challenge of maintaining product integrity in temperature-controlled supply chains. The pharmaceutical industry is a crucial subset affected by this problem.

Safeguarding the efficacy and safety of life-saving medications through stringent regulations, precise temperature control, robust security, and meticulous tracking is a complex task. Third-party logistics providers (3PLs) play a vital role in this field. They bring specialized expertise and resources to navigate the intricacies of pharmaceutical logistics, ensuring product safety, regulatory compliance, and efficient delivery.

Unique Challenges of Pharmaceutical Logistics

Pharmaceutical logistics faces a unique set of hurdles. These challenges demand specialized expertise and precise execution.

Sensitivity to Temperature and Time

Pharmaceutical products are often incredibly sensitive to temperature fluctuations. This necessitates robust cold chain logistics. Cold chain logistics involves maintaining a consistent temperature range throughout the entire supply chain. This includes storage, transportation, and handling.

Temperature excursions, even brief ones, can compromise the efficacy and safety of medications. They can lead to product degradation, spoilage, or render the product unusable. Certain medications are also extremely time-sensitive. Delivery delays can have serious consequences for patients. Proper handling and expedited shipping are crucial for these life-saving drugs.

Stringent Regulatory Requirements

The pharmaceutical industry operates under a strict regulatory framework. This framework is designed to protect patient safety. The FDA sets forth numerous regulations and guidelines. These include current Good Manufacturing Practices (cGMP), which outline quality control requirements.

The Drug Supply Chain Security Act (DSCSA) is another critical regulation. It mandates track and trace capabilities throughout the pharmaceutical supply chain. Compliance with these regulations is complex. It requires meticulous documentation, validation, and adherence to strict protocols. Track and trace capabilities are essential for ensuring product integrity. They also help prevent counterfeiting and diversion.

Security and Chain of Custody

Preventing counterfeiting and theft is a top priority. Counterfeit medications pose a serious threat to public health. Robust security measures are essential throughout the supply chain. These measures include secure storage facilities, access controls, and surveillance systems.

Maintaining the chain of custody is also critical. This involves documenting the movement and handling of products at every stage. Serialization, which involves assigning a unique identifier to each product, plays a key role in ensuring product integrity and traceability.

Special Handling and Storage Requirements

Different pharmaceuticals have different handling and storage requirements. Some medications, like controlled substances, require extra security precautions. Biologics, which are often derived from living organisms, may need very specific temperature ranges and handling procedures.

Specialized facilities and equipment are often necessary to meet these diverse needs. This might include temperature-controlled warehouses, refrigerated trucks, and specialized packaging.

How 3PLs Address Pharmaceutical Challenges

3PLs offer a range of specialized services to tackle the complexities of pharmaceutical logistics. They act as vital partners, providing the expertise and resources needed for success.

Specialized Infrastructure and Technology

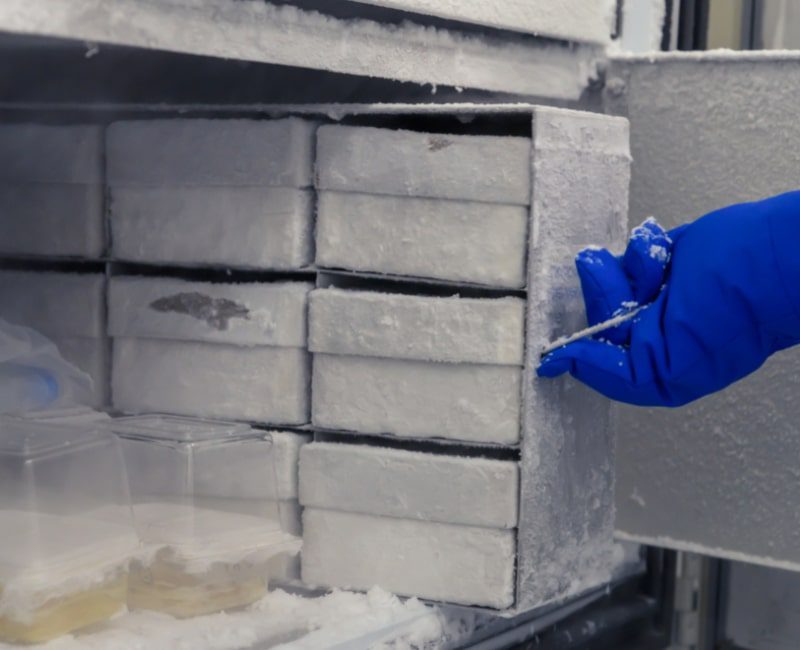

3PLs invest heavily in specialized infrastructure. Temperature-controlled warehouses are essential for maintaining product integrity. These facilities are carefully monitored and validated to ensure consistent temperatures.

Temperature-controlled transportation is equally important. Refrigerated trucks and specialized packaging help protect products during transit. Real-time tracking and monitoring systems provide visibility throughout the supply chain.

These systems allow for proactive intervention if temperature deviations occur. Validated systems are critical. Validation ensures that all processes and equipment meet regulatory requirements and function as intended.

Regulatory Compliance Expertise

Staying up-to-date on constantly evolving regulations is a challenge. 3PLs dedicate resources to regulatory compliance. They closely monitor changes in guidelines and relevant regulations.

3PLs have experience with audits and inspections. This experience helps them ensure compliance for both themselves and their clients. 3PLs also play a crucial role in helping manufacturers meet compliance requirements. They provide guidance and support in navigating the complex regulatory landscape.

Robust Security Measures

Security is a top priority for 3PLs; secure facilities with controlled access are essential. These facilities often include surveillance systems and other security measures. Chain-of-custody protocols are strictly enforced. This ensures that the product’s journey is documented and tracked at every step.

Advanced tracking and monitoring technologies enhance security. These technologies can help detect and prevent theft, counterfeiting, and diversion.

Customized Solutions and Scalability

Every pharmaceutical company has unique needs. A good 3PL partner will tailor their services to meet these specific requirements. They work closely with clients to develop customized solutions.

Scalability is another key benefit. 3PLs can easily adjust their services to accommodate changes in demand. This flexibility is invaluable in the dynamic pharmaceutical market.

Optimized Transportation and Distribution Networks

3PLs leverage their extensive networks to ensure timely delivery. Route planning and optimization are essential tools to help minimize transit times and reduce costs.

3PLs utilize various transportation modes, including trucks, planes, and ships. They choose the most appropriate mode based on the product’s needs and delivery requirements.

The Benefits of Partnering with a 3PL for Pharmaceutical Logistics

Partnering with a 3PL offers numerous advantages for pharmaceutical companies, including cost savings, efficiency gains, and risk mitigation.

Cost Savings

3PLs can significantly reduce logistics costs for pharmaceutical companies. They achieve this through several strategies:

- Economies of scale: 3PLs handle logistics for multiple clients. This allows them to negotiate better rates with carriers and other service providers.

- Optimized resource utilization: 3PLs have the expertise and technology to optimize warehouse space, transportation routes, and staffing levels. This efficient use of resources minimizes waste and reduces costs.

- Reduced capital expenditures: By outsourcing logistics, pharmaceutical companies avoid the need to invest in expensive infrastructure, technology, and personnel.

Improved Efficiency and Speed

3PLs streamline logistics processes, leading to improved efficiency and speed:

- Streamlined processes: 3PLs have established and refined logistics processes. This expertise allows them to handle operations more efficiently.

- Improved delivery times: 3PLs optimize transportation networks and routes. This optimization leads to faster delivery times.

Enhanced Focus on Core Business

Pharmaceutical companies excel at developing and manufacturing life-saving medications. Outsourcing logistics allows them to concentrate on these core competencies. They can dedicate their resources to what they do best, rather than managing complex logistics operations.

Reduced Risk and Liability

Partnering with a 3PL can significantly reduce risk and liability:

- Compliance: 3PLs are experts in regulatory compliance. They help pharmaceutical companies navigate the complex regulatory landscape, minimizing the risk of non-compliance.

- Security: 3PLs implement robust security measures to protect products from theft, counterfeiting, and damage. This reduces the risk of product loss and liability.

- Product safety: 3PLs adhere to strict quality control procedures to ensure product safety. This minimizes the risk of product recalls and other safety issues.

Choosing the Right 3PL Partner

A strong partnership can significantly impact efficiency, cost, and compliance. Here are some key factors to consider when choosing a 3PL for your pharmaceutical company:

Experience in the Pharmaceutical Industry

Look for a 3PL with proven experience in the pharmaceutical industry. They shouldn’t just move boxes; they should understand the intricacies of handling pharmaceuticals. Inquire about their experience with specific types of pharmaceuticals relevant to your products, such as biologics, controlled substances, or temperature-sensitive medications.

Ask about their understanding of the regulatory landscape and their experience working with pharmaceutical manufacturers. A 3PL with deep industry knowledge will be a more valuable partner.

Robust Quality Management Systems

A robust quality management system (QMS) is essential; your 3PL should have documented procedures and processes in place to ensure product quality and safety at every stage of the supply chain.

Look for certifications like ISO 9001, which demonstrates a commitment to quality management, or GDP (Good Distribution Practice), which specifically addresses the distribution of pharmaceuticals. A strong QMS should encompass everything from receiving and storage to transportation and documentation.

Advanced Technology and Infrastructure

Advanced technology and infrastructure are crucial for efficient and compliant logistics. The right 3PL will have state-of-the-art temperature-controlled warehouses with validated systems. Real-time tracking systems should provide complete visibility into the location and condition of your products.

Validated software is essential for managing inventory, tracking shipments, and ensuring regulatory compliance. A 3PL that invests in technology demonstrates a commitment to innovation and efficiency. They should also have robust IT systems to ensure data security and integrity.

Strong Track Record of Compliance

Compliance with regulations is non-negotiable in the pharmaceutical industry. Choose a 3PL with a strong track record of compliance with all relevant regulations.

A 3PL with a history of compliance issues could put your business at risk. Inquire about their experience with FDA audits and inspections. A proactive approach to compliance is essential.

Customization and Flexibility

Every pharmaceutical company has unique needs. Your 3PL should be able to tailor its services to meet your specific requirements. Don’t settle for a one-size-fits-all approach. Discuss your specific needs and challenges with potential 3PL partners.

Flexibility and scalability are also important. The right 3PL will be able to adapt to changes in demand and product volume. They should be able to scale their services up or down as your business grows or changes. A flexible partner will be able to adapt to the dynamic pharmaceutical market.

Streamlining Pharmaceutical Supply Chains

Pharmaceutical logistics is a complex and demanding field. It presents unique challenges related to temperature sensitivity, stringent regulations, security, and specialized handling. Partnering with a specialized 3PL offers significant advantages in navigating these complexities. Expertise, technology, and unwavering compliance are the cornerstones of successful pharmaceutical logistics.

At Hanzo Logistics, we are committed to supporting our clients in navigating these complexities and ensuring the safe and efficient delivery of their products. Our experience and innovative solutions allow us to provide tailored services for the pharmaceutical industry, addressing the specific needs and challenges of companies within this sector.